Business

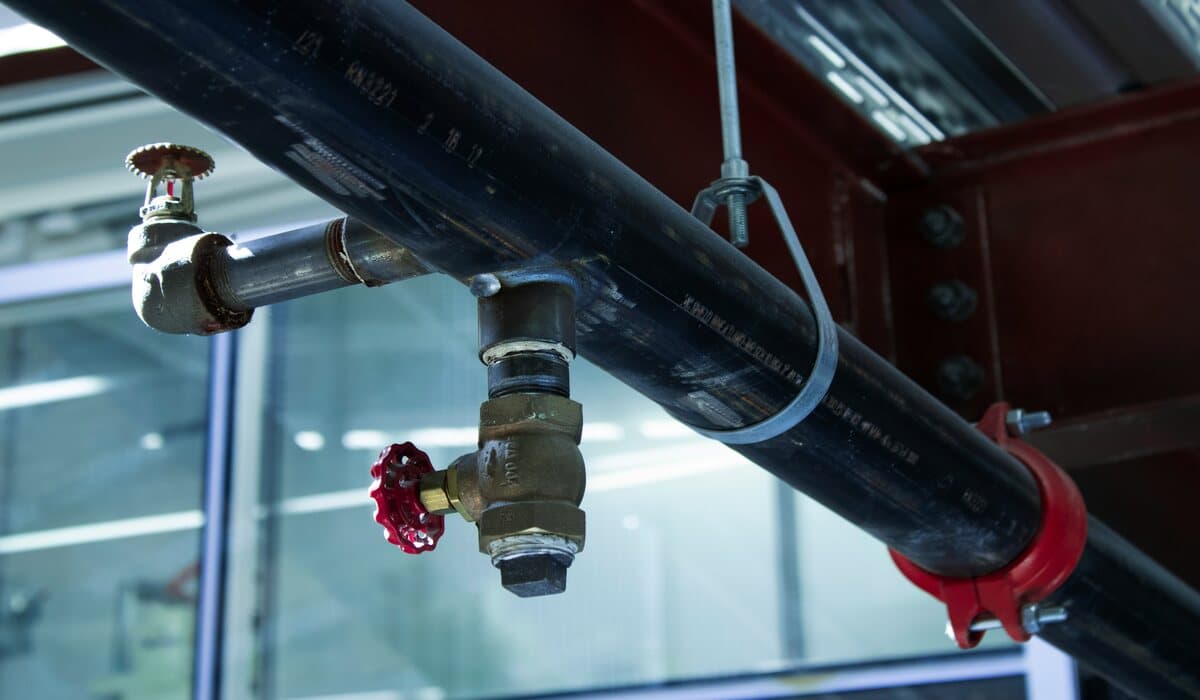

Fisher Gas Purge Valve: A Comprehensive Guide

Gas systems are essential in many industries. One crucial component in these systems is the Fisher gas purge valve. Understanding its function, benefits, and maintenance can greatly enhance your system’s efficiency.

What is a Fisher Gas Purge Valve?

A Fisher gas purge valve is a specialized device designed to control gas flow in pipelines. It allows for the safe venting of gas during maintenance or operational adjustments. This valve ensures that gas is not released into the environment unnecessarily.

Understanding Its Functionality

The primary function of the Fisher gas purge valve is to maintain safe pressure levels within a gas system. When pressure builds up, the valve opens, allowing gas to escape safely. This process prevents potential hazards and ensures smooth operation.

Importance in Natural Gas Systems

In natural gas systems, safety is paramount. The Fisher gas purge valve plays a critical role by ensuring that the system can vent excess gas safely. Without this valve, pressure could build up to dangerous levels, leading to potential explosions or leaks.

Key Features of Fisher Valves

Fisher gas valves are known for their high-quality construction and innovative design. Here are some notable features:

Durability and Reliability

Fisher valves are built to withstand harsh conditions. They are made from high-quality materials that resist corrosion and wear. This durability ensures a longer lifespan, reducing replacement costs over time.

Versatile Applications

These valves are used in various applications, from residential gas systems to large industrial operations. Their versatility makes them an excellent choice for any gas system requiring reliable flow control.

Benefits of Using a Purge Valve

Investing in a Fisher gas purge valve offers several advantages:

Enhanced Gas Flow Control

A purge valve allows for precise control over gas flow. This capability helps maintain consistent pressure levels in the system, ensuring optimal performance.

Increased System Efficiency

With effective gas flow control, your system operates more efficiently. This efficiency can lead to reduced operational costs and improved overall performance. A well-functioning valve can also minimize waste, making your system more eco-friendly.

| Benefit | Description |

|---|---|

| Enhanced Safety | Prevents overpressure and potential hazards |

| Cost-Effectiveness | Reduces maintenance and operational costs |

| Versatile Usage | Suitable for various applications |

| Long Lifespan | Durable materials ensure reliability |

Installation Guide for Fisher Gas Purge Valves

Proper installation is crucial for optimal performance. Here’s a step-by-step guide:

Step-by-Step Installation Process

- Preparation: Ensure you have all necessary tools and materials.

- Shut Down System: Always shut down the gas system before installation.

- Locate the Installation Site: Choose a location that allows easy access for future maintenance.

- Install the Valve: Position the valve correctly in the pipeline. Ensure that it aligns with the flow direction indicated on the valve.

- Secure Connections: Tighten all connections to prevent leaks.

- Test the System: Once installed, gradually restore gas flow and monitor for leaks.

Tools and Materials Required

- Wrench set

- Teflon tape

- Safety goggles

- Fisher gas purge valve

- Pipe fittings

Maintenance Tips for Optimal Performance

Regular maintenance ensures that your Fisher gas purge valve functions efficiently.

Routine Checks and Procedures

- Inspect for Leaks: Regularly check all connections for signs of gas leakage.

- Clean the Valve: Keep the valve clean from debris and buildup that may obstruct its operation.

- Check Seals: Inspect seals for wear and tear. Replace them as necessary to prevent leaks.

Common Issues and Troubleshooting

- Valve Does Not Open: This may indicate a malfunctioning actuator. Check the actuator for damage or misalignment.

- Leakage at Connections: Tighten the fittings or replace worn seals.

Comparing Fisher Valves with Other Brands

When considering a gas purge valve, it’s essential to compare options.

Performance Standards

Fisher valves often outperform competitors in durability and efficiency. Their construction standards set them apart in reliability. Many users report fewer maintenance issues with Fisher valves compared to other brands.

Cost-Effectiveness

Although Fisher valves may have a higher upfront cost, their durability and efficiency can lead to significant savings in the long run. Investing in quality can reduce overall operational costs.

Conclusion

The Fisher gas purge valve is a vital component of any gas system. Its ability to control gas flow safely and efficiently cannot be overstated.

Investing in a high-quality valve ensures the safety and reliability of your system. Regular maintenance will extend the valve’s lifespan and improve overall performance.

When choosing a gas purge valve, consider Fisher’s superior quality and reliability. You’ll find it a worthwhile investment in the safety and efficiency of your gas system.

-

Tech2 months ago

Tech2 months agoTwastia.com: Your Go-To for Digital Solutions

-

Delaware2 months ago

Delaware2 months agoNew Castle Beer: A Delaware Favorite and Its Rich History

-

Features2 months ago

Features2 months agoCleetus McFarland Net Worth in 2024

-

California2 months ago

California2 months agoWhere to Buy Kangertech T3S Coils in Oakland, California: Best Options

-

California2 months ago

California2 months agoCosts of Root Canal in Berkeley, Oakland, and Across California

-

Idaho2 months ago

Idaho2 months agoRake Up Boise 2024: Guide to Idaho Community Cleanup Event

-

Texas2 months ago

Texas2 months agoDallas Cowboys Helmet: A Texas Icon and NFL Legacy

-

Alaska2 months ago

Alaska2 months agoAre Wintergreen Plants in Alaska Edible?